REFRACTORY

INDUSTRIAL

OUR BUSINESS

Refractory Installation Equipment

The World leader in Refractory Installation Technology

Solving costly lining problems became our business

For nearly thirty years, Gradmatic Equipment has significantly influenced the foundry industry by providing innovative technology to line coreless induction furnaces with dry, refractory materials. Specializing in refractory installation and vibration, our product primarily focuses on improving the industrial furnace lining process for worker safety and efficiency.

Refractory Installation And Vibration System Overview

Our Products

Refractory Installation Equipment

GRADMATIC

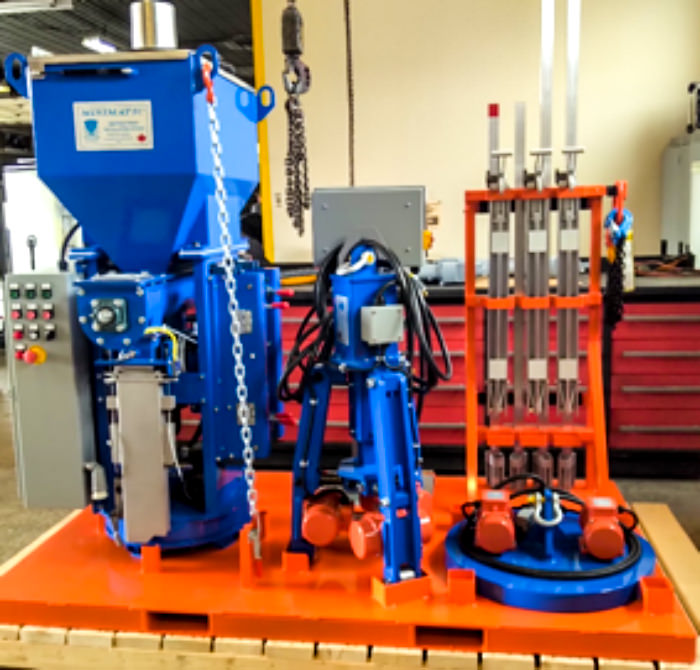

Refractory Installation System (RIS)

Induction Furnace Heating Equipment

The Refractory Installation System (RIS) performs two functions: it simultaneously dispenses dry refractory between the furnace wall and form and automatically deaerates the material.

GRADMATIC

INSTACENTR® Form Centering Tool

for Furnace Lining Installation & Replacement

A set of three InstaCentr® spacing tools are used to quickly and accurately center the form(er) within the furnace, for the entire length of the form(er) in about 10 minutes. For furnaces 12 tons or larger, four tools are required.

GRADMATIC

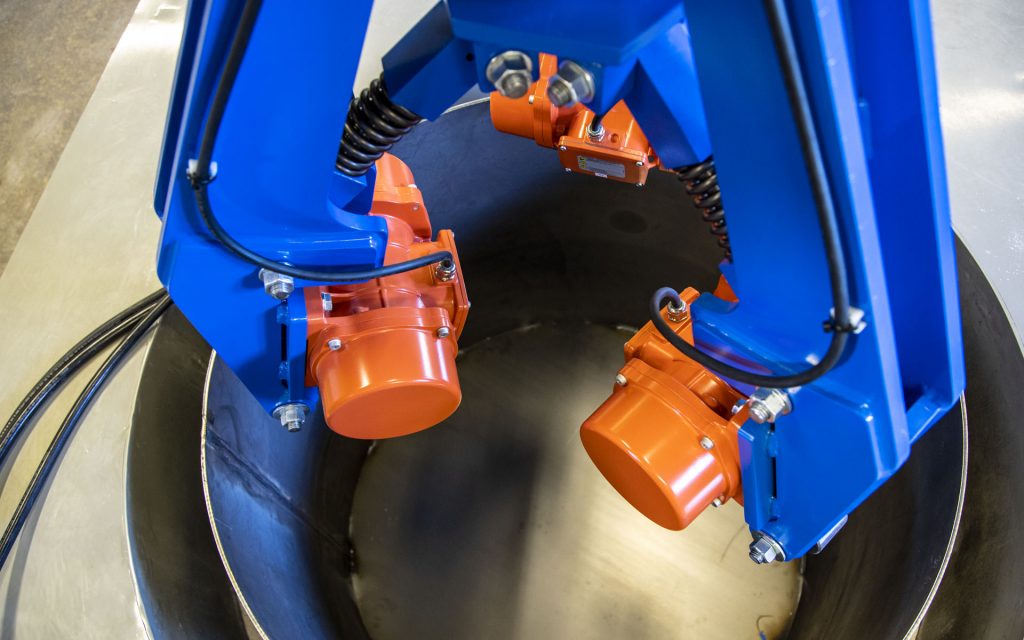

Refractory Vibration System

The Refractory Vibration System is comprised of two components

The electric bottom or floor vibrator plate and an electric sidewall vibrator unit

Both units are operated from the furnace deck by a control stand.